Initial Mock-up

Dec 2nd, 2013 by huntek3

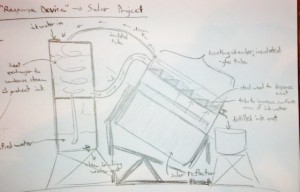

We began the project by looking at the old reflector frame and speaking to past cohorts of the Ghana Exchange Program. Speaking to these students allowed us to quickly examine the changes that would need to be made to the existing steel frame with regards to its rotation around the reactor chamber and tracking of the sun. We determined that the depth of the trough would need to be adjusted to move the axis of rotation closer to the frame.

Previously, the trough had been too shallow (i.e. the curve radius too large) which pushed the focal point six feet away from the reflector. This would mean that at midday when the reflector curve perpendicular to the ground, the reactor would be over nine feet in the air. This would create both accessibility and mechanical problems, as longer, more flexible tubing (to connect the reaction chamber with the cooking vessel) would be needed to accommodate for the large movements and more care would need to be taken to minimize the inevitable heat losses gained by the longer connection tube.

We also spoke to Professor Jensen about possible reactor designs. Previously, the reactor was an open steel container. Much of the energy gains that were made, were lost to convective and conductive heat transfer, so the ink-water never reached temperatures above room temperature. From our discussions we determined that we would need to use either a flat-plat or evacuated tube reactor.