Lamination

Dec 2nd, 2013 by huntek3

Lamination Methods

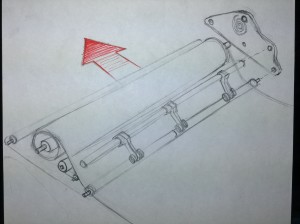

Lamination Rollers

The lamination rollers available in Ghana are two rubber-steel rollers in 24” length, while the reflector film and surface to be laminated are in 48” length. The original trial of letting two person laminating separately with the two rollers did not work out, in that pressure was not distributed evenly with two people rolling, which lead to wrinkles on the material.

Figure 1&2: Original Lamination Rollers

For the second iteration of the lamination rollers, we seek to join the two rollers together and let one person be in charge of rolling. Since the rollers are hollow inside, we purchased a piece of threaded rod of length xx- which is more than twice the length of one single roller, to fit inside the rollers from heads to tails, then tight the two ends with corresponding nuts, and thus, joined the rollers together. This solution works well in solving the lamination problems from the rollers’ aspect. However, the lamination process is more difficult to practice as we performed 3 trials.

Lamination Process

The reflector metal is cleaned thoroughly using isopropyl alcohol in order to wipe off dust on the substrate and to minimize the negative effects of residues. And then the surface is gently dried using paper towel.

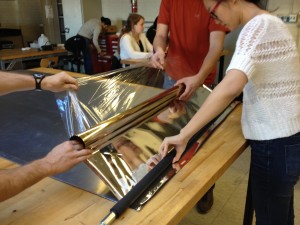

A transparent plastic coating is tended to be removed from the unwind shaft. Two people standing by the sides of the reflector surface had to remove the plastic coating 1 inch by 1 inch to make sure the film is lined up on both sides with the substrate. One person standing at the perpendicular side in between the two people is in charged of rolling.

To perform the lamination with the least wrinkling, the reflector film must be pulled as straight and tight as possible to ensure forces are distributed evenly from each person pulling. However, over strength can cause worse wrinkling because the reflector film would be permanently stretched. The effect of over power could be observed and further prevented by timely recognizing the wave patterns on the incoming part of the reflector film.

A step by step guide to DIY lamination is shown as following with pictures:

Line up the film with the reflector metal and leave 2 inches spare space on each end. Cut the film with scissors.

Line up the edge of the reflector film with the reflector metal. Tear off the plastic coating, let 2 people hold the film and plastic and one laminate with hands for the first 5-10 inch length of reflector surface.

Use the roller to continue laminating while two people by the sides pulling straight and tight of the film and plastic coating.

Trim the edges.

Use the edge tape provided with the mirror film to tape the edges.